From the Permian (And More) To You: Explaining U.S. Refineries

As we see the rapid increase in oil and natural gas demand across the world, from Beaumont, Texas to Carson, California to Whiting, Indiana, U.S. refineries are working overtime to meet global demand for products produced from petroleum. These refineries are a crucial part of turning U.S. oil and natural gas production from the Permian, Bakken, and the Gulf of Mexico, into the products we use every day including gasoline, plastics and more.

From jet fuel to iPhones

Refineries can be intimidating. Oftentimes, refining complexes span across massive facilities with multiple structures, resembling Emerald City from Oz. But through the massive structures and complicated systems, the process can be distilled (pun intended) into three steps: separation, conversion, and treatment. From these three steps, we are able to create everything from butane to jet fuel to plastic.

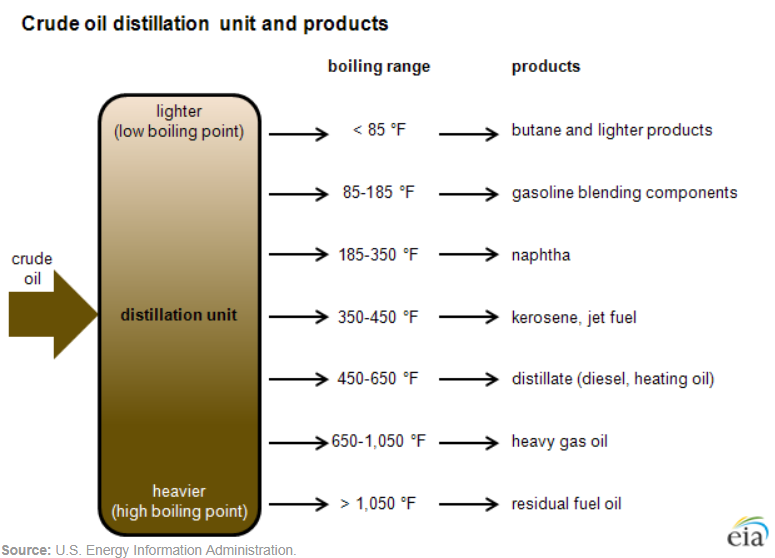

Separation: The U.S. Energy Information Administration (EIA) explains separation rather simply: “modern separation involves piping crude oil through hot furnaces.” From here, both liquids and vapors are captured and separated. Depending on the resulting products density, it will either float up and be recondensed into liquids or sink down into heavier fuels.

Conversion: Once separated and distilled, the resulting products are converted into gasoline or other products with crackers, and no we are not talking about the snack accompanying your charcuterie board. According to the EIA, “the most widely used conversion method is called cracking because it uses heat, pressure, catalysts, and sometimes hydrogen to crack heavy hydrocarbon molecules into lighter ones.”

Treatment: The final step involves combining the separate products from the processing units, like the crackers, to produce one final product easily deliverable to market.

Bringing production and products together

Many facilities are expanding their refining capacity to be further able to process U.S. crude oil, particularly along the Gulf Coast. Until recently, a large portion of Gulf Coast refineries processed heavier crude oil, more compatible with Gulf production, but the shale revolution completely changed that dynamic, creating the need for expanded refining capacity for oil form Texas and New Mexico.

Oil and natural gas companies are quickly responding to this demand, in order to keep up with U.S. production. For example, ExxonMobil recently announced its Beaumont Refinery would expand its refining capacity by an estimated 65 percent, with a large focus on processing crude oil from the Permian Basin. The project, named the Beaumont Light Atmospheric Distillation Expansion (BLADE) is expected to come online in 2023.

Chemistry within the community

Refineries are crucial parts of communities, offering both employment and economic support for these regions of the country. Both during the construction and operations of these refineries, companies invest heavily in becoming an integral part of the community. For example, during the early days of the COVID-19 pandemic, companies like ExxonMobil and Valero both produced hand sanitizer to be distributed to hospitals and medical centers amid national shortages.

The longstanding relationship between companies and the communities surrounding their refineries has allowed them to help the surrounding communities directly, even in the worst times. During Hurricane Harvey, ExxonMobil provided a temporary pump to provide water for Beaumont after severe floods knocked out the main intake valves, leaving the region without water. Not only do these refineries produce the molecules that power our lives, but the companies (and people) will do anything to ensure the wellbeing of the residents in the communities where they operate.

Conclusion

As a key aspect of energy security, the country’s ability to refine domestically produced oil will ensure we continue to see the benefits of domestic oil production. Unfortunately, due to a variety of factors, oil imports have been steadily increasing, meaning the oil we are using may not be subject to our country’s strict environmental standards. With U.S. refiners adapting their operations to produce oil from the Permian Basin, we will be able to better respond to increased oil demand is a safe and sustainable manner.

No Comments